- Home

- /

- Moulds manufacturing

- /

- Injection moulds

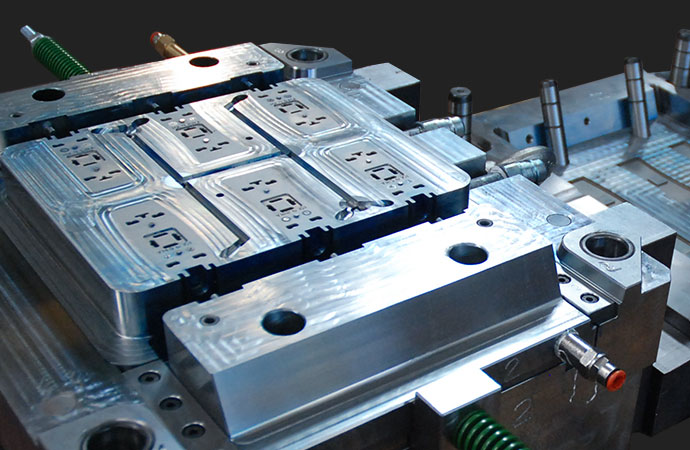

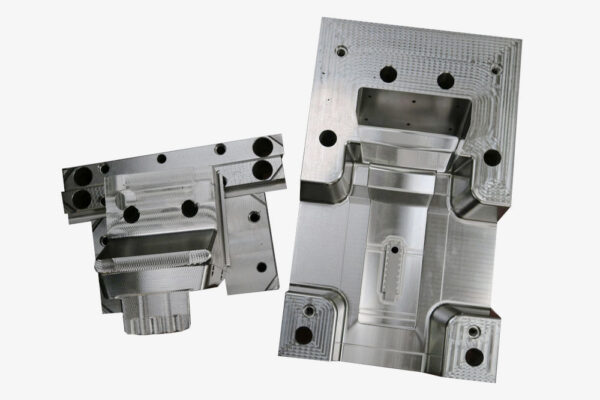

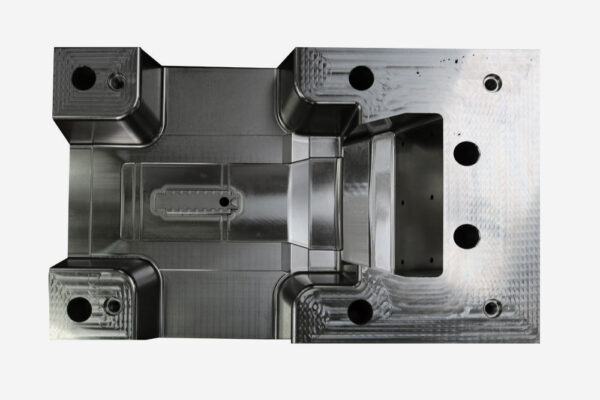

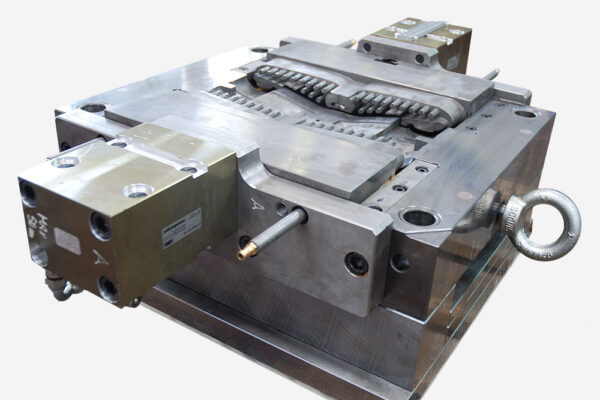

Injection moulds

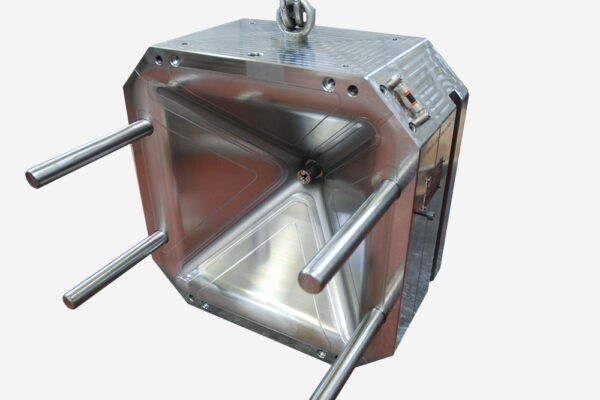

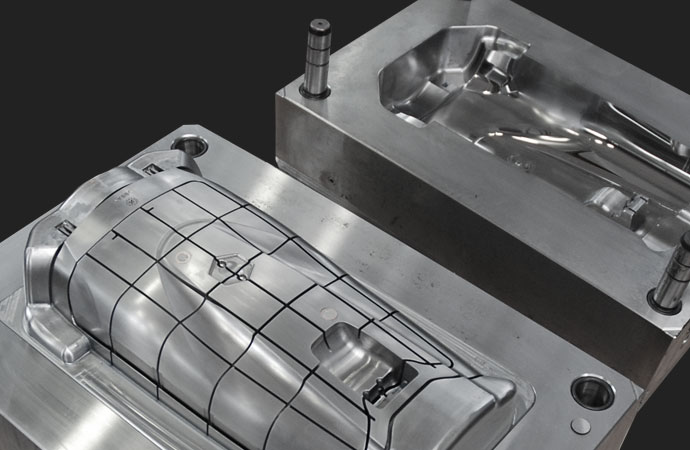

Design and construction of injection moulds

Since 1988 Eurostampi has been the reference point for the design, construction and maintenance of injection moulds for plastics, to meet all customer needs.

We offer a complete service that ranges from the evaluation of the feasibility of the project and costs, to the co-design, and the industrialization of the specifics, to then move on to the design and construction of the injection mould, up to the functional checks and testing.

Injection moulds for plastic material

Thanks to the continuous investments in industry 4.0, a modern machine fleet and the skills of a highly specialized team, Eurostampi produces injection moulds for plastic materials tailored to the most varied industrial sectors, offering the best value for money.

Our staff guarantees high quality injection moulds, built with the utmost precision and reliability that has consistently distinguished the company.